The automated guided vehicles (AGV)

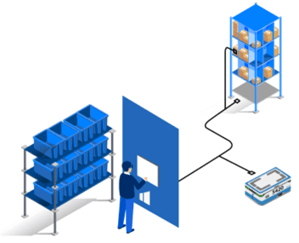

The packing station is a workstation where operators handle the items scheduled for shipping. They must scan, pack, and have the items ready for shipping. The most problematic issue is that precious time consumes while gathering all the needed products for an order. In most cases, the working space and the storage areas are cluttered from trying to reach items underneath other items. This causes disorder.

The traditional packing station consists of a workstation where employees can operate. There is also a racking system from which they have to extract the needed goods for transport. AGVs (Automated Guided Vehicles) systems decongest the workflow, save time and space, and maintain the optimal arrangement at the workplace. This way, they streamline the workspace and increase production.

-

Automated Guided Vehicles (AGVs)

Product information

The automated guided vehicles are designed for use in the logistics industry. They are a devoted partner that optimizes and automizes fast material transport. They do this by being able to identify, lift, carry and bring back a high rack filled with different categories of products in the exact location. This way, the warehousing processes fasten and are closely traced. This can only lead to increased production and process boost.

The AGVs that Eurobox has in stock are low-height robots. They go under the racks placed in a deposit, and transport them from the storage area to the picking station. Their mechanism allows the guided vehicles to operate with high racks. This happens due to their sturdiness and impressive precision. Once it arrives at the picking station and the needed item is removed from the rack, the robot will return the rack to its initial position. This maintains a clean and well-organized workplace. They can lift up to 600 kg, and their travelling speed is 1.5 meters per second while empty. They travel at 1.2 meters per second while they carry a rack.

One of the revolutionary aspects that makes the AGV a professional, time-saving and production-increasing solution is the impressive number of 600 picks per hour that each picker provides. The approximate increase in production that this product guarantees is 40%.

Using AGVs and having to monitor a robotized packing station has multiple perks. The personnel will benefit from real-time collaboration with a professional system. It guarantees a solution that is adjustable and adaptable to any working space. In addition, the further material flow is automated using automated guided vehicles. More value is added to the business.

With the AGVs that Eurobox has to offer, saving up to 30% of the congested working space is simpler. Robots in a warehouse will move around seamlessly and provide great flexibility in the working area. This technology will develop any business. It provides a simple and robust mechanism with fast and effective maintenance.

A company will discover the solution for a methodical and continuous product supply by opting for the automation of all operations and relying on technology. This is the first step in increasing competitiveness and sales. These are some top aspects a well-organized company looks forward to achieving.

Efficiency & Flexibility

Efficiency & Flexibility

The AGVs that Eurobox proposes are in direct contact with the person responsible for their routes. They operate using an intelligent system that allows fast changes in their routines. Users can reorganize their movement areas and update the position of specific racks of products.

They provide complete and broad software. AGVs will represent a customer-friendly solution for logistics, automotive warehouses, and healthcare sectors.

The navigation process

The navigation process

The automated guided vehicles use Wi-Fi to navigate throughout a warehouse space. They move around by following their guiding floor lines. These do not use adhesives and are easy to install. They adjust to any flooring surface without changing the warehouse’s infrastructure. They are 160 mm wide and 1 mm thick and can be attached to any surface. This way, they are a universal and adaptable option for warehouses. Each AGV has a well-defined route to avoid bumping into another picker. This means no damage will be done to the robots or the expensive items placed in racks.

AGVs’ service life

The fast charging system and powerful AGVs’ batteries facilitate a 24/7 operating cycle. When the AGVs’ battery is low, they will move to the charging station and enter the recharging process. After charging, they will re-enter the working cycle and provide a continuous operating cycle.

The battery that they operate on is Li-Ion type. It is the fastest type of rechargeable battery. In addition, they promise long service life at high-quality standards and low maintenance. The automated guided vehicles’ recharge time is only 2 hours and 30 minutes. Their operating life is 14 hours.

The interaction between the host and AGVs

The vehicles maintain a crucial information flow between the robots and the host. This is due to the developed communication technology. The information transferred between the two parts refers to order execution, management of the AGVs’ mobility, and improved connection between the automated elements and the client’s control unit.

The host is the person in charge of the AGVs’ movements and the commands they must obey. The host is responsible for changes to the robots’ routes, tasks and travel pathways. Since the transit is automated, two-way contact with the systems is necessary. Due to the interface of the automated guided vehicles, the storage is automated as well. The interface enables a two-way connection. The data capture system is in charge of connecting to the devices mounted surrounding the AGVs.

High-quality connection network

Utilizing technology is crucial in today’s world. It has made daily tasks and processes more accessible. The best way to streamline operations and reduce decision-making time is by using the real-time connection and benefiting from digital access to every owned automated guided vehicle. Its owner can supervise, diagnose, update, and personalize each one. By using Wi-Fi, this connectivity is easily achieved.

Real-time data, operational warnings, connectivity to additional data sources, remote software updates, and the ability to work with automated guided vehicles are all achievable by allying with automated robots for product handling.

More perks of choosing to work with AGVs

Provided safety – the automated guided vehicles are safe to use in robots and people’s shared spaces. The rack-moving systems only follow the guidelines placed on the floor

Quick ROI (return of investment) – clients increase production and obtain efficiency when working with the AGVs. The investment made when purchasing them is quickly recovered (less than two years)

Modularity – Installing Eurobox’s automated guided vehicles takes only two to three weeks. They will not disrupt the usual operations processes. They will also not need future investments to benefit from their services. The robots are a complete solution.