Conveyors

Conveyors are modern handling systems that transport materials or finished goods. Handled items extend from the production and processing equipment to the packing and dispatch areas. They can cover the entire distance between different loading and unloading points. This is due to their modular construction. It ensures a quick movement of the transfer products and generates a well-coordinated supply flow. In addition, the travel distances for the operators become shorter. They can handle larger volumes of goods in the same amount of time. This happens through the use of adapted ergonomic equipment. These aspects maintain the operators’ satisfaction at a raised level. They are healthy, and their work performance increases.

-

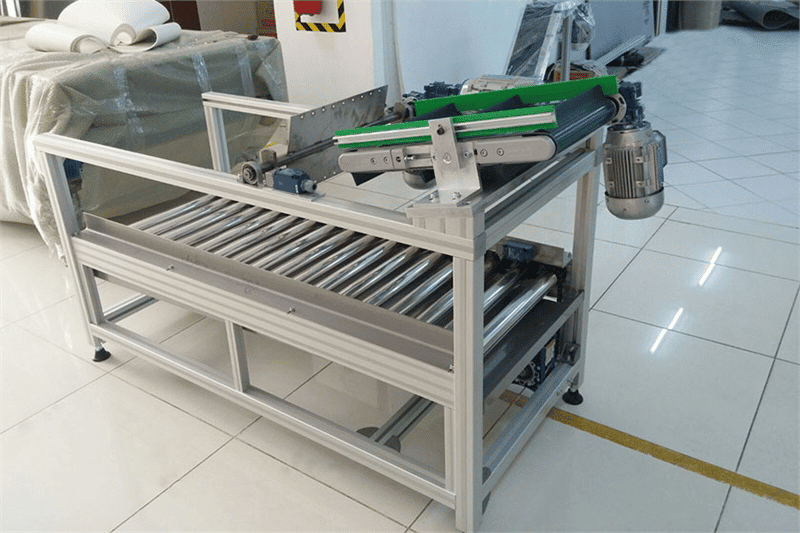

Stationary roller conveyors

Product information

Roller conveyor systems facilitate the advancing of items on special cylinders. They ensure the progress of material through the friction of the load that carries out a rolling motion. The goods move in a controlled manner from the input to the picking area along a gradient. It consists of a continuous frame with roller tracks. This ensures a smooth and safe passage of the load. This decreases the handling time and effort and increases internal production.

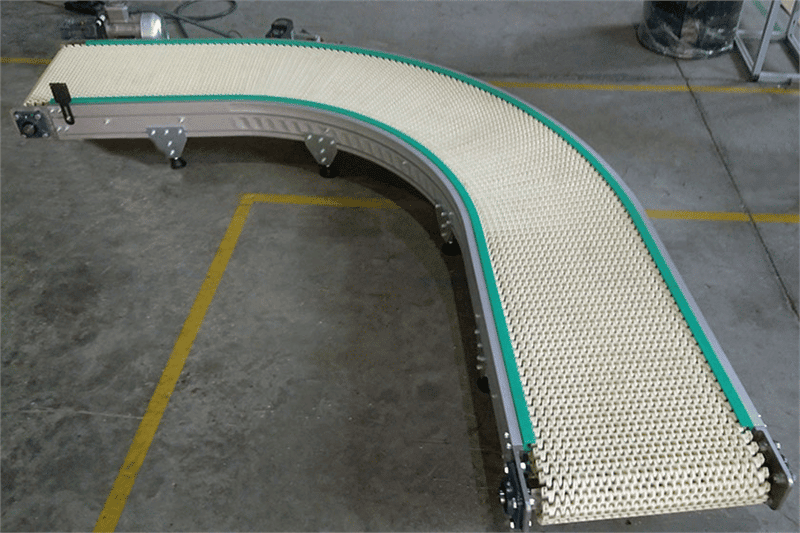

Operators can install the conveyor rollers on a modular principle. The rollers may vary in length, clearance and roll diameter. Many materials are available, such as galvanized, rubber-made, or PVC-coated rollers. The selection depends on the nature of the application. Roller conveyors cater for item size, weight, volume and tenderness. Their height is adaptable to the space upgrade requirements. They can have straight or curved installation formats. This option suits companies that must exploit the available space to a maximum. Roller covers and other optional components can be added to customize the conveyors for specific tasks.

Roller conveyors are robust and can handle continuous use. In case defects occur, the solution is to replace the affected parts. They especially suit companies that use medium and smaller sizes and weights packaging. These packages can be cardboard and plastic boxes or containers. Their transfer surface can be stable enough for loads with rimmed or uneven bottoms. Examples are drums, pails, pallets and larger bags. The lateral guides can have small rollers. This increases efficiency and ensures an even smoother flow up to the end of the line.

Roll conveyors can be gravity (downhill installed with a slight slope) or electrically driven. Gravity conveyors are environmentally friendly. They require no power supply to ensure the continuous flow of materials. This eliminates the need for complex electrical cabling or the electric power itself. Plus, they do not need additional operations and maintenance. Some models suit temporary set-up and others for permanent installation. This offers the user great freedom when choosing the right conveying solution.

In the case of the gravity roller tracks, a few elements are of great importance for a functional system. They have the right combination of conveying weight, roller material and brake options. Clients can opt for brake elements with direct and indirect action. They help achieve an optimum continuous flow. These brake carrier rollers regulate the speed of the conveyed materials on the gravity roller track. They keep them at a constant and controlled speed. With a thoughtful design, gravity-driven conveyor technology can fit in larger material handling systems. For example, operators can install it between two electric belts or roller conveyors.

Specialists recommend the motorized versions of the stationary roller conveyors for transporting goods over longer distances. Clients can use them inside production or distribution facilities. Due to the powered system, they can move the goods on a horizontal plane within an optimum time. Their speed is adjustable. In consequence, there is total control over the process. This helps reduce the potential risks of damaging the goods.

Further, the conveyors can split into zones where they are each tracked. This allows the respective section to run only when an item is on the conveyor. This helps companies reduce costs and improve handling efficiency. In addition, they can have hinge sections for passage.

Powered roller conveyors can handle heavier loads. Due to this, they are often used in the fabrication industry. Here, they help with the automatic replenish of materials and parts. For this option, the diameter of the roller is significant to the application. Larger rollers can carry more weight at a time. Drive rollers are small, automated modular units. They receive direct driving mechanical input from an electric internal motor. The system can be customized to be caused by an external power source. Such sources can be chains or belts, which are more common for curves.

-

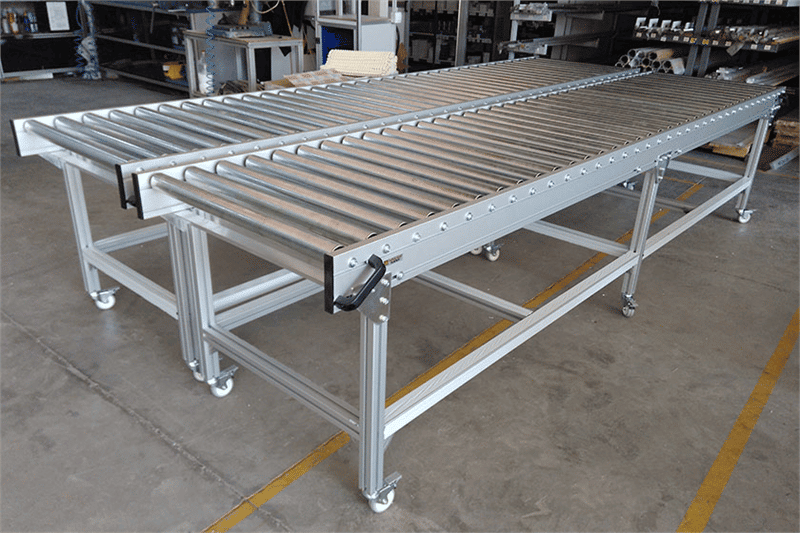

Extandable roller conveyors

Product information

Unlike the fixed (stationary) roller conveyors, the extendable versions have expanding frames. This allows companies to store them when not in use. They are practical and ergonomic because they can be compacted to just one small part of their extended length. The system’s main advantage is the mobility and flexibility it offers the staff. Operators can quickly move and rearrange it upon need. This way, the dead space – created by pallets or roll-cages – reduces or even eliminates.

Expandable roller conveyors are cost-effective handling solutions. They find use in large distribution centers and smaller companies requiring one unit. They allow an easy, safe and fast load transfer in or out of the vehicles and containers. They operate between different packaging and flexible assembly line points, as well. Parcel post and logistic service providers, producers and distributors widely use them. A few examples of handled goods are textile items, electronic devices, a wide range of flat-based loads and lightweight loose cargo.

On the running track, extendable conveyors can have rollers and roller tracks. They enable a greater transfer speed of the load. Standard and optional conveyor widths allow companies to choose the suitable version for various goods dimensions. The support legs, adjustable between different heights, offer strength and rigidity. Swivel castors bring maximum agility. They incorporate foot-operated brakes to fix the system in the intended place. Larger optional diameter castors allow easier rolling over rough or uneven surfaces. In contrast, optional connecting brackets can quickly and easily connect two or more conveyors to expand the system.

Similar to the stationary roller conveyors, the scissor roll conveyors versions can be gravity-driven or motorized. The powered ones benefit packaging applications, parcel distribution centers and machine-to-machine-linking. They provide a digitally controlled spacing of the packages or items. This helps with easier handling and barcode scanning. Conveyor speed is adjustable regarding travelled distances per minute. The intelligent optic stop solutions prevent packages from falling off the conveyor at the discharge end. After removing the package, the conveyor starts automatically. It moves until the next packet arrives at the discharge point.

These independent conveyor lines allow the creation of a curved route, including S-shaped. It happens due to their high pliancy. This advantage improves industrial safety and production in workplaces where the space matter is essential. The scissor conveyors with rollers can extend around obstacles and different dedicated areas. The extendable roller conveyor system can be constructed on a telescopic principle. This applies to those companies that operate in a straight and broader space.

-

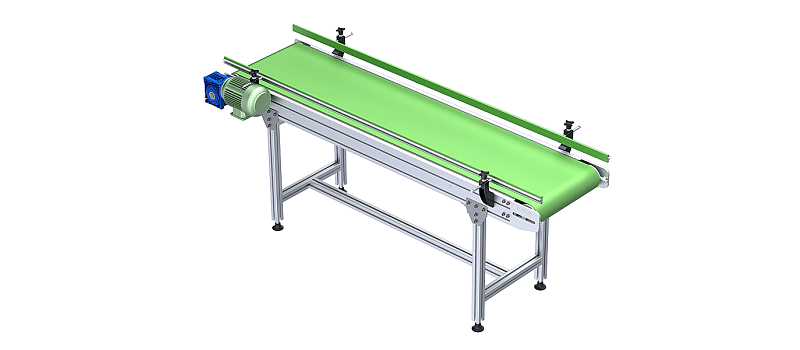

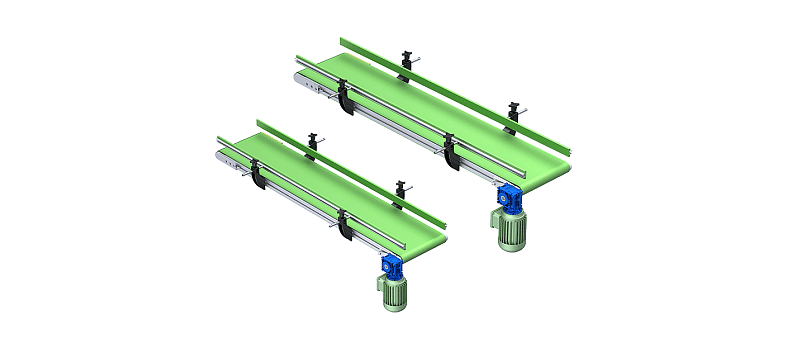

Stationary belt conveyors

Product information

Belt conveyors, or conveyor belts, are simple and efficient systems that move individual items and packages with products or bulk materials. They exist in every industry and every internal workflow process. This extends from fabrication and assembly to distribution and warehousing. The fields where belt conveyor technology is most popular include automotive and aerospace. They exist in packaging and print finishing, bottling and canning, chemical and pharma, and the food industry. Besides the industrial settings, belt conveyors are also installed in airports, supermarkets and restaurants.

The system has different pulleys and a closed-loop conveyor belt that rotates around them. One or more pulleys from the system can be powered. This helps move the belt in the right direction. The transfer belt of the conveyors can be produced from a wide variety of materials. Choosing the right material depends on the use. Further, it can have a closed smooth surface, a perforated one if the products need to be ventilated, or a wired surface for high heat resistance.

Conveyor belt systems can be enclosed to prevent contamination and loss of material. For example, they can be open if included in assembly or bar-coding lines. The width, lengths and height (the latter fixed or adjustable, if necessary) are configured depending on the particularities of the application. The moving speed is also adjustable to ensure the proper transfer of each batch of items. They offer a limited speed range, and the velocity ratio may vary during moving. In addition, belt conveyors are economically versatile. They offer the possibility of being loaded virtually from any place along the belt. They can further be installed in straight, curved or inclined settings.

The inclined versions come in the form of elevator belt conveyors. They transfer the items between operation lines with height differences. These are provided with regularly placed belt separators. These hold the products while lifted or lowered on the conveyor, so they do not overturn. Further, the system can set the goods in their personal space. It happens in applications where they must remain divided until they can be lifted from the conveyor. Employees can use these climbing or downhill belt conveyors to remove scraps and waste from production or sorting units.

Different configurations of safety rims can also be mounted. This prevents the products from falling laterally. If required, a small tunnel or a protection chamber can be placed at the entry of the conveyor. This is needed to stop the eventual spilling of materials. The working level can be set between 15-45 degrees. The slope is available in straight lines or the shape of “L” or “Z” letters. Miniature conveyors are also available for those applications that require rapid and easy transmission of small-size items. All belt conveyors can have wheels to increase work flexibility and allow rapid movement toward the intended area.

-

Telescopic belt conveyors

Product information

Telescopic belt conveyors allow easy and fast automatic loading and unloading of loose-loaded cargo to and from the vehicles. They are provided with wheels that enable users to move them anywhere inside the work area. Operators can connect them to different stationary conveyors. Their main solid frame provides stability and strength. At the same time, a unique multi-connector system holds together the telescoping modules when the system extends.

Telescopic conveyors can be installed in a wide range of configurations. They can be provided, at the end, with different optional components such as platforms and ramps. The platform models are handy for unloading loose cargo from the truck, such as goods packed in separate bags or cardboard boxes. In addition, they allow the operators to enter the vehicles, reach every inner item and unload it in the easiest way. The platform is constructed with ample space. It can accommodate two persons standing on the platform while working at adjustable heights.

The platform raises or lowers with the telescopic conveyor in a smooth and safe way. This is possible by using foot pedals and hand control buttons to adjust their position and have the parcels within easy reach permanently. The system notably increases the unloading throughput and provides an effective workflow. It also allows the trailers to be filled up to the full height. This reduces the transport cost per parcel.

For the automatic loading of the trucks with bulk packages, the suspended part of the telescoping driven belt conveyor is pivoting in all directions, from side to side. The reason is to distribute the cargo in an even level of filling. Different-sized boxes and bags are gently released one at a time from the end of the telescoping conveyor. As a result, they are naturally mixing to close the vacant gaps in the vehicle. They use the space almost up to the full height. The system is designed with a short release distance. This way, items are placed instead of dropped to prevent the package from damaging.

During operation, the system detects the obstacles and avoids possible collisions to protect the cargo. In addition, its sensors can be adjusted to suit the height of the parcels. This helps in preventing a package jam during the load process. As online shopping customers demand fast delivery options, the loading method allows e-commerce sector companies to handle all types of cargo in one load efficiently. This helps shorten the overall deadlines.

Besides saving time, the system is reducing human intervention. It requires minimal physical effort to load the vehicles but minimal supervision. This way, the risk of workforce injury no longer exists. Operators can carry out their activity in a safer, less demanding work environment. Additional optional safety features bring an even more advanced security degree to the conveying system. Some examples are a light barrier that detects human presence and stops the equipment automatically or audio and visual signals to indicate when the conveyor is in operation.

Different producers, online retailers and parcel carriers use loading and unloading systems to automate their internal logistics processes. Loading and unloading the trailers at the door increases work capacity, cuts handling costs, and optimizes warehouse activity. Operators no longer have to carry items by hand. Drop-off or pick-up areas can be placed directly next to them. One of the main additional benefits of the system is that it can expand beyond the constraints of space limitation. Also, it requires no additional loading and unloading of vehicles or other equipment.

The extension and retraction of the telescopic belt conveyors are fully motor-driven. They have a quick response to the operator’s actions. The main body and extension dimensions can be customized. This is to allow access to the entire length of the transport vehicles. Telescoping conveyors can further have rollers instead of belts. The roller models enable the personnel to move the items take-away and drop-off points upon need. They can be installed in a motorized version or telescope gravity roller conveyors.

-

Chain conveyors

Product information

Chain conveyors are durable transport systems that move large and heavy products along production or assembly lines. They are suitable for items not transported on roller or belt conveyors. Some examples are industrial containers, pallets, racks and any other product with a sturdy lower surface. The system is employed in automotive, metal processing, and similar heavy-use applications. They can easily convey the parts between various production facilities or warehouse stations.

The chain conveyors are recommended for cyclic and phased product movements. They can be used as part of a more complex production automation system. They also allow sturdy operation in reverse and a high resistance to elongation. The operation principle is based on a circular chain mounted on two toothed wheels. It provides a continuous belt motion on a fixed length. The system’s design can have different drive variants and a series of interlocking wear strip parts, making them easy to replace. However, the chains need more frequent cleaning and lubricating. Still, on the other hand, these qualities make them suitable for oily environments.

The main advantage of chain conveyors is that they can integrate with an automated system. They successive goods taking over, even one after another. They are often used to configure complex interlinking solutions in a dual or multiple-line structure. Chain conveyor belts operate at a constant and low speed to prevent the products from shaking and overturning. This robust yet dynamic transfer technology is reliable and resistant to prolonged and intensive use. The goods are moved efficiently, safely and gently to ensure stability and reduce the slipping risks.

Conveyor chains offer endless transport solutions for internal logistics. They extend from standard range to custom options for components and entire configurations. They can have lifting and transferring modules, positioning and rotating units, stoppers, and control components. These confer high performance and consistency to the handling operations.

Conveyor systems transport the goods alone or with their carriers. Some examples are vacuum-formed and injection molded component holders, trays, crates and pallets, and cardboard boxes. In manufacturing sites, the equipment can be configured on the way back. This aims to return the empty reusable packaging at the processing or assembly points. Level differences can be overcome with the help of inclined elevator conveyors, which transfer various items to vertical distances in a short time.

Conveyor systems should be present, especially in busy production units, warehouses and logistic centers. They increase the automation degree and speed up the internal flow. Materials can travel in different directions. For example, this is useful when sending them between the opposite ends of a processing plant with an extended surface. Transfer conveyors are also recommended. They optimize the buffer stocks management and deliver products sequentially for a highly tailored supply. They can be equally helpful in applications where light and numerous articles must be moved often. It is essential in transferring heavy or bulky materials, as well.

Clients can fully customize the system to suit each industrial field, such as manufacturing and processing activities. The transport support is subject to various materials and layouts, such as rollers, belts and chains. The length, width and height can be configured according to the product’s dimensions, the available internal space, and the needs of the working procedures.