Horizontal stretch wrapping machines

Stretch wrapping machines are equipment for fixing and compacting palletized goods. This is necessary to ensure safe transport. They help reduce costs and time. In addition, they protect fragile, expensive and odd-shaped items.

Automated stretch wrapping devices can integrate with ease into conveyor lines. The machines do not require any effort from the operators. They can complete an entire operating cycle without interrupting. Their resilience and precision ease and accelerate the packing process.

Semi-automated stretch wrapping equipment requires low effort from the operators. They only have to initiate and guide the wrapping operation. Employees have to cut the foil after each wrapping cycle. They can use particular devices to make this operation.

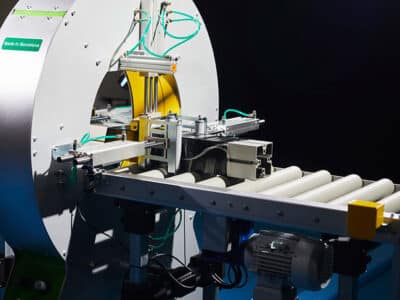

Automatic horizontal stretch wrapping machines

Automatic horizontal stretch wrapping machines offer high-performance packaging of the products. They do not require physical effort from the employees. Belt or roller conveyors transport the products. They integrate the system into automatic lines inside production or dispatch areas. The machines are recommended for high-volume applications. They can pack straight or rounded-shaped products that need to be dispatched permanently. This offers increased packaging speed. In addition, clients save operating costs and time.

The models for straight goods use adjustable top presses. They alternately fall on and rise from the products. They use lateral guides for holding light loads to keep them in place while the wrapping process completes. This wrapping equipment is available in several diameters. This way, it allows the wrapping of various products. It can handle small items like moldings and bulky products like cupboards or wall panels. These full automatic orbital wrappers are suitable for packing slender. In addition, they can wrap long products, like shelves, pipes and profiles. The automatic wrapping machines for round products are designed to protect circular goods automatically. Examples of such items are rolls of flexible pipes, cables and tires. Both wrapping machine versions hold and stabilize goods packed in bundles.

Some of these versatile orbital wrappers are designed with photocells for product detection. These machines’ control panels come with an integrated touch screen. It allows the operators to manage the settings in an easy and intuitive way. They can choose the customized programs and adjust the rotation speed. The wrapping system is widely used for colored, painted or polished surfaces. These require increased protection during storage and transit.

Automated orbital stretch wrappers eliminate the need to use interleaved buffer materials. They stop the use of materials and handling procedures related to manual packing, as well. The reason is that they are subject to the operators’ daily lack of time and work fatigue. These machines decrease body movements and stretch, familiar to hand wrapping, which can lead to back injuries. At the same time, they can work many hours daily while delivering high-quality packaging.

| Reference | Dimensions (mm) | Coil width (mm) | Power supply (V) | Installed capacity (kW) | ||

|---|---|---|---|---|---|---|

| MI 04 | 2245 x 2350 x 2699 | 125/250 | 400 V | 2 | View product |

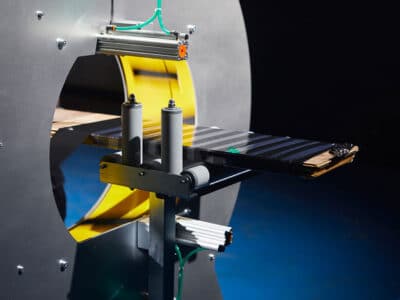

Semi-automatic horizontal stretch wrapping machines

They orbit the stretch film around the products and cover them with foil. At the same time, the operator keeps them in their place manually to ensure correct packing. The models designed for round items require the hand rotating of the respective products – on the special rotation unit – to enable the wrapping procedure. In the semi-automatic orbital stretch wrapping machines for straight products, the goods are placed on linear roller conveyors and only hand-guided by the operator to move through the stretch foil.

Other models are specifically designed for wrapping cardboard boxes of different sizes. Cardboard material can get wet or damaged in various ways during transport. Due to this, the wrapping procedure protects the content against moisture and other external factors. These motorized wrapping machines allow the operators to pack even 3 or 4 such boxes at a time. They are stacked one on top of another for maximum efficiency with minimum effort. They can be provided with roller conveyors in front of or behind the wrapping small table. It enables the package to slide back and forth while an operator guides it.

The operator initiates the wrapping process by stepping on a foot button or hand-pulling the end of the stretch film and placing it on the cardboard box. After the first complete wrapping, if necessary, the employee can pick up or pull back the package on the conveyor and then turn it over to wrap the package around the width. The cardboard box wrapping machines are provided with a height-adjustable work table. This ensures a more simple and ergonomic work process. At the end of the packing process, the foil can be cut manually or by special devices.

Spiral wrapping machines reduce manual labour and increase speed and precision inside each packaging process. This allows the staff to perform more tasks in a shorter time and lower the delivery delays. Useful options and devices enable fast, durable and reliable packing with stretch film. They consist of a safety foot switch and touch screen with explanatory GIFs.

Semi-automatic packaging equipment can be designed for any product, from small profiles to tires and large wooden boards. Depending on the products’ height and width, they come in different ring dimensions to suit each application better.

| Reference | Dimensions (mm) | Coil width (mm) | Power supply (V) | Installed capacity (kW) | ||

|---|---|---|---|---|---|---|

| MI 05 | 1375 x 500 x 2180 | 125 | 400 V | 1.1 | View product |

| MI 03 | 1010 x 1450 x 1550 | 125 | 230 | 0.75 | View product |